OEM Customized Horizontal Boring Milling Machine - Brass connector cover on boiler heating system – Ideasys

OEM Customized Horizontal Boring Milling Machine - Brass connector cover on boiler heating system – Ideasys Detail:

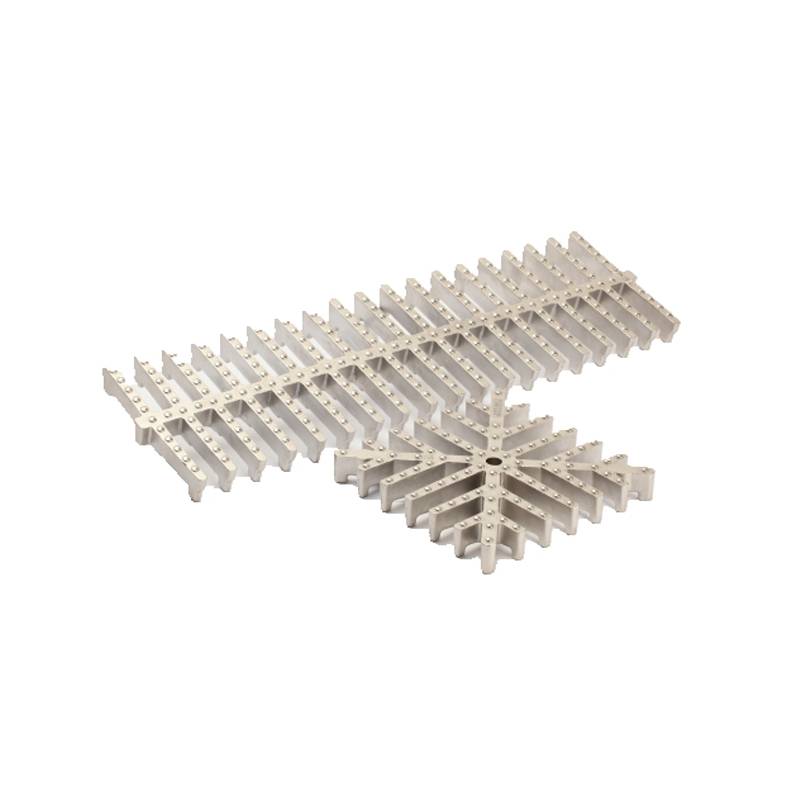

| Produst | Name | Material | Weight |

|

Brass connector cover on boiler heating system | Brass | 65g |

How are brass fittings made?

The first step in this process is to cut the copper bar into the length of the part being made. It is then heated to achieve permeability and pressed between the dies under high pressure. It is then cooled, and the flash is trimmed and the forging blank is machined to complete the assembly.

Why do we use brass?

Brass is most widely used in decoration and mechanical fields. Due to its unique properties, including corrosion resistance, common uses of brass include applications requiring low friction.

Why use brass for gas fittings?

Brass can also withstand low temperatures. This is important because vaporization of LPG causes cylinders and valves to become very cold. Brass is not brittle at low temperatures, unlike mild steel.

Does brass corrode in water?

In general, the zinc loss of brass after immersion is relatively fast, which leads to metal weakening and makes its structural integrity in danger. In addition to immersion in water, brass is a very suitable metal for outdoor applications due to its amazing durability.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for OEM Customized Horizontal Boring Milling Machine - Brass connector cover on boiler heating system – Ideasys , The product will supply to all over the world, such as: Azerbaijan, Belgium, Kenya, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.